Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Product Range

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. Gear Wheel

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Shaft

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft’s production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CZPT has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CZPT products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

Our Advantages

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Material: | 17CrNiMo6 |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Customization: |

Available

| Customized Request |

|---|

What is a drive shaft?

If you notice a clicking noise while driving, it is most likely the driveshaft. An experienced auto mechanic will be able to tell you if the noise is coming from both sides or from one side. If it only happens on one side, you should check it. If you notice noise on both sides, you should contact a mechanic. In either case, a replacement driveshaft should be easy to find.

The drive shaft is a mechanical part

A driveshaft is a mechanical device that transmits rotation and torque from the engine to the wheels of the vehicle. This component is essential to the operation of any driveline, as the mechanical power from the engine is transmitted to the PTO (power take-off) shaft, which hydraulically transmits that power to connected equipment. Different drive shafts contain different combinations of joints to compensate for changes in shaft length and angle. Some types of drive shafts include connecting shafts, internal constant velocity joints, and external fixed joints. They also contain anti-lock system rings and torsional dampers to prevent overloading the axle or causing the wheels to lock.

Although driveshafts are relatively light, they need to handle a lot of torque. Torque applied to the drive shaft produces torsional and shear stresses. Because they have to withstand torque, these shafts are designed to be lightweight and have little inertia or weight. Therefore, they usually have a joint, coupling or rod between the two parts. Components can also be bent to accommodate changes in the distance between them.

The drive shaft can be made from a variety of materials. The most common material for these components is steel, although alloy steels are often used for high-strength applications. Alloy steel, chromium or vanadium are other materials that can be used. The type of material used depends on the application and size of the component. In many cases, metal driveshafts are the most durable and cheapest option. Plastic shafts are used for light duty applications and have different torque levels than metal shafts.

It transfers power from the engine to the wheels

A car’s powertrain consists of an electric motor, transmission, and differential. Each section performs a specific job. In a rear-wheel drive vehicle, the power generated by the engine is transmitted to the rear tires. This arrangement improves braking and handling. The differential controls how much power each wheel receives. The torque of the engine is transferred to the wheels according to its speed.

The transmission transfers power from the engine to the wheels. It is also called “transgender”. Its job is to ensure power is delivered to the wheels. Electric cars cannot drive themselves and require a gearbox to drive forward. It also controls how much power reaches the wheels at any given moment. The transmission is the last part of the power transmission chain. Despite its many names, the transmission is the most complex component of a car’s powertrain.

The driveshaft is a long steel tube that transmits mechanical power from the transmission to the wheels. Cardan joints connect to the drive shaft and provide flexible pivot points. The differential assembly is mounted on the drive shaft, allowing the wheels to turn at different speeds. The differential allows the wheels to turn at different speeds and is very important when cornering. Axles are also important to the performance of the car.

It has a rubber boot that protects it from dust and moisture

To keep this boot in good condition, you should clean it with cold water and a rag. Never place it in the dryer or in direct sunlight. Heat can deteriorate the rubber and cause it to shrink or crack. To prolong the life of your rubber boots, apply rubber conditioner to them regularly. Indigenous peoples in the Amazon region collect latex sap from the bark of rubber trees. Then they put their feet on the fire to solidify the sap.

it has a U-shaped connector

The drive shaft has a U-joint that transfers rotational energy from the engine to the axle. Defective gimbal joints can cause vibrations when the vehicle is in motion. This vibration is often mistaken for a wheel balance problem. Wheel balance problems can cause the vehicle to vibrate while driving, while a U-joint failure can cause the vehicle to vibrate when decelerating and accelerating, and stop when the vehicle is stopped.

The drive shaft is connected to the transmission and differential using a U-joint. It allows for small changes in position between the two components. This prevents the differential and transmission from remaining perfectly aligned. The U-joint also allows the drive shaft to be connected unconstrained, allowing the vehicle to move. Its main purpose is to transmit electricity. Of all types of elastic couplings, U-joints are the oldest.

Your vehicle’s U-joints should be inspected at least twice a year, and the joints should be greased. When checking the U-joint, you should hear a dull sound when changing gears. A clicking sound indicates insufficient grease in the bearing. If you hear or feel vibrations when shifting gears, you may need to service the bearings to prolong their life.

it has a slide-in tube

The telescopic design is a modern alternative to traditional driveshaft designs. This innovative design is based on an unconventional design philosophy that combines advances in material science and manufacturing processes. Therefore, they are more efficient and lighter than conventional designs. Slide-in tubes are a simple and efficient design solution for any vehicle application. Here are some of its benefits. Read on to learn why this type of shaft is ideal for many applications.

The telescopic drive shaft is an important part of the traditional automobile transmission system. These driveshafts allow linear motion of the two components, transmitting torque and rotation throughout the vehicle’s driveline. They also absorb energy if the vehicle collides. Often referred to as foldable driveshafts, their popularity is directly dependent on the evolution of the automotive industry.

It uses a bearing press to replace worn or damaged U-joints

A bearing press is a device that uses a rotary press mechanism to install or remove worn or damaged U-joints from a drive shaft. With this tool, you can replace worn or damaged U-joints in your car with relative ease. The first step involves placing the drive shaft in the vise. Then, use the 11/16″ socket to press the other cup in far enough to install the clips. If the cups don’t fit, you can use a bearing press to remove them and repeat the process. After removing the U-joint, use a grease nipple Make sure the new grease nipple is installed correctly.

Worn or damaged U-joints are a major source of driveshaft failure. If one of them were damaged or damaged, the entire driveshaft could dislocate and the car would lose power. Unless you have a professional mechanic doing the repairs, you will have to replace the entire driveshaft. Fortunately, there are many ways to do this yourself.

If any of these warning signs appear on your vehicle, you should consider replacing the damaged or worn U-joint. Common symptoms of damaged U-joints include rattling or periodic squeaking when moving, rattling when shifting, wobbling when turning, or rusted oil seals. If you notice any of these symptoms, take your vehicle to a qualified mechanic for a full inspection. Neglecting to replace a worn or damaged u-joint on the driveshaft can result in expensive and dangerous repairs and can cause significant damage to your vehicle.

editor by CX 2023-05-29

China High quality gearbox marine helical gear reducer high torque helical gearbox speed reduce motor with worm gearbox carbon fiber drive shaft

Warranty: 3 many years

Relevant Industries: Resorts, Garment Outlets, Developing Materials Stores, Production Plant, Equipment Fix Retailers, Foods & Beverage Manufacturing unit, Farms, Restaurant, House Use, Retail, Foodstuff Shop, Printing Outlets, Construction works , Vitality & Mining, Foodstuff & Beverage Stores, Marketing Firm

Bodyweight (KG): sixty five

Tailored help: OEM, ODM, OBM

Gearing Arrangement: Helical

Output Torque: 3.5~500N.m

Input Pace: 1450/960rpm

Output Pace: 14-280rpm

Ratio: 3.77~50.four

Certification: ISO9001-2008

Mount Situation: Foot Mounted

Bearing: C&U,LYC, HRB, Cam Sprocket EX5 Dream 28T Racing Adjustable Bike Timing Gear For Honda ZWZ,NSK

Shade: RAL9006(grey) OR RAL5571(blue)

Packaging Particulars: Wood containers , Cantons packed in 1 pallet

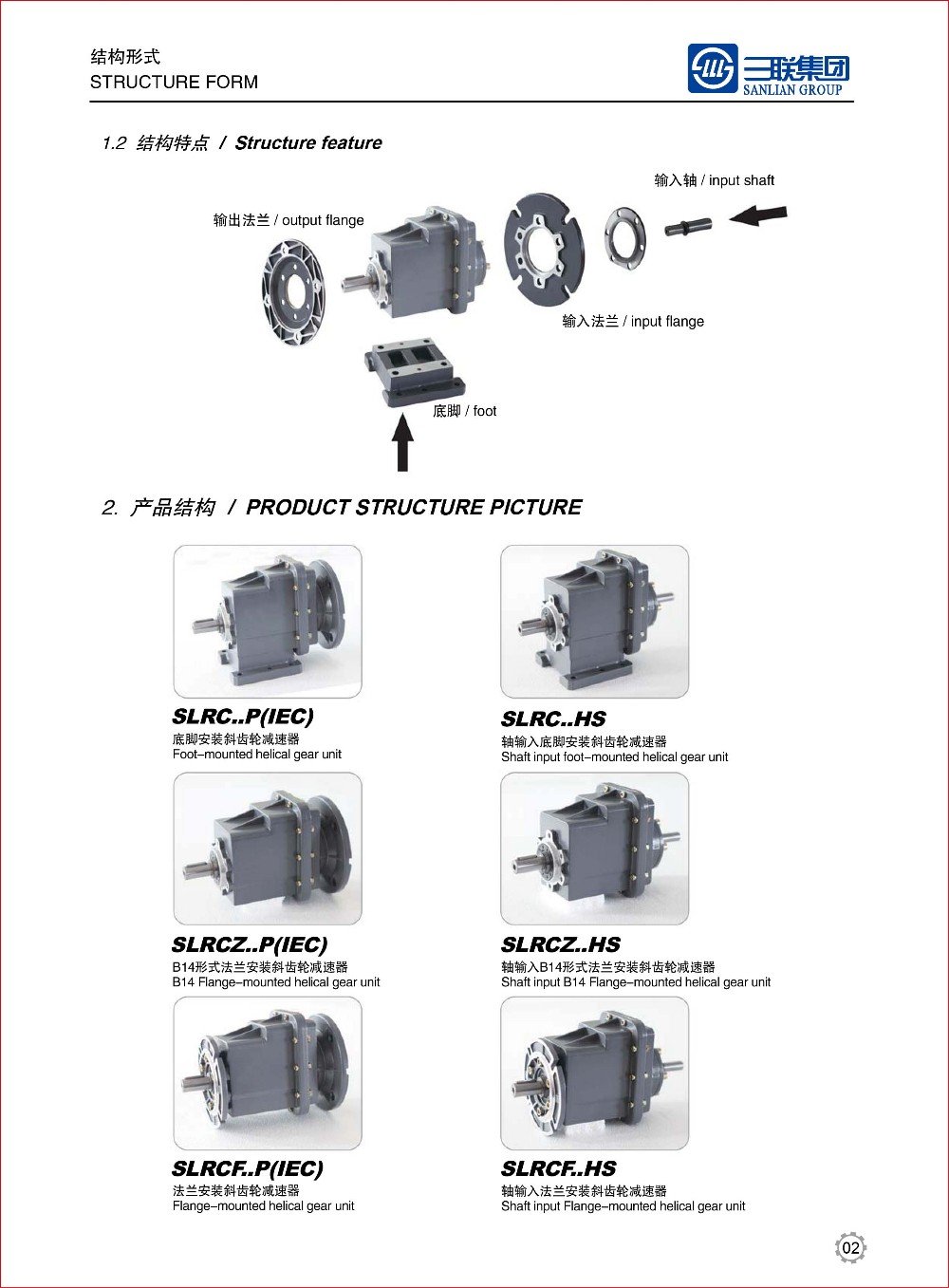

Large high quality china marine gearbox RC01 helical equipment box harmonic generate CZPT reverse gearbox

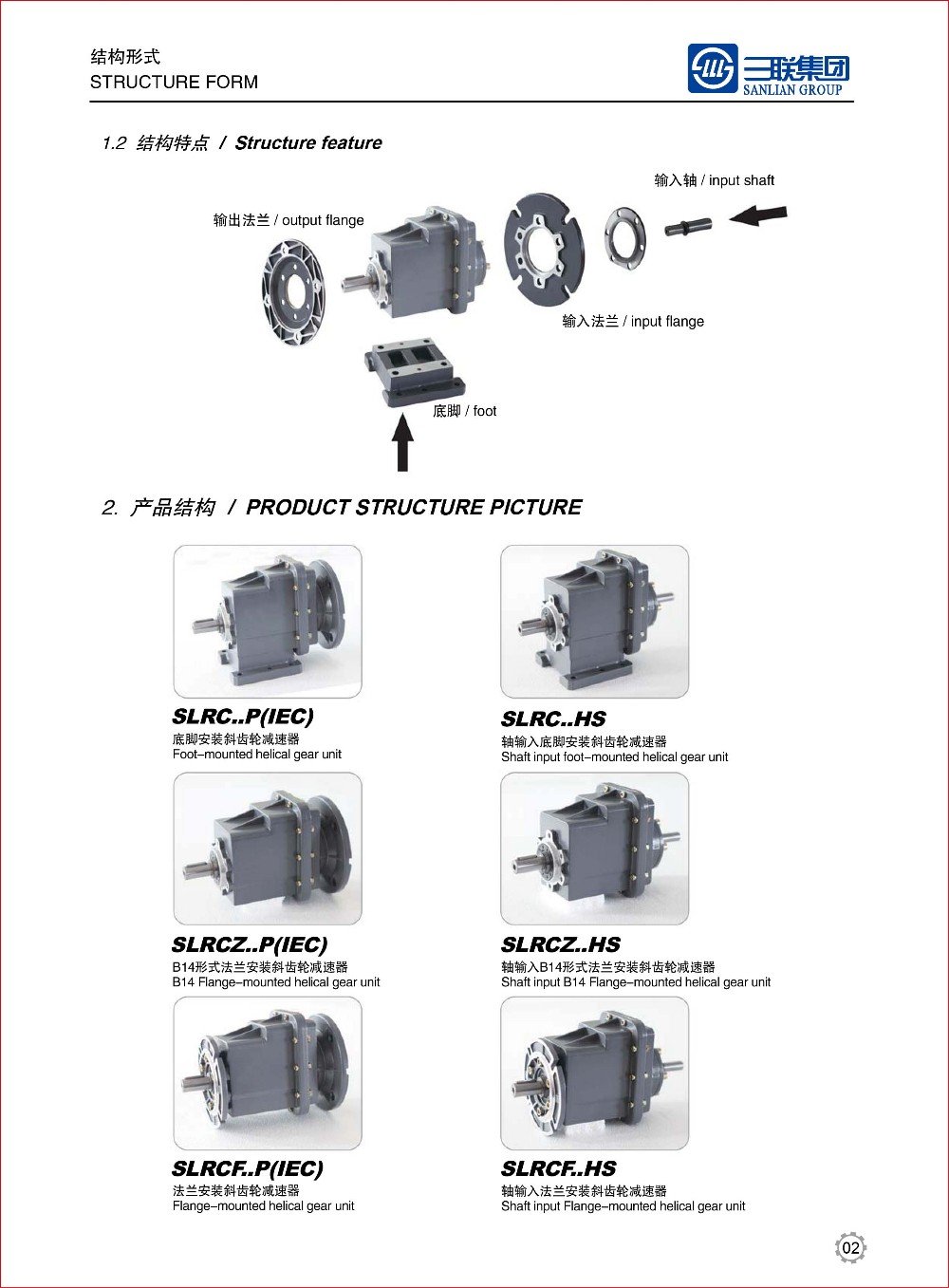

The highly modular is a style characteristics of SRC helical gearboxes selection. It can be linked respectively with motors these kinds of as standard motor,brake motor,explosion-proof motor,frequency conversion motor,servo motor,IEC motor and so on. This sort of solution is widely utilized in generate fields these kinds of as textile,foodstuff,ceramics packing,logistics,plastics and so on. It is possible to set up the version necessary utilizing flanges or toes.Merchandise characteristics:SLRC sequence helical gear models has more than 4 kinds,energy .12kw-4kw,ratio3.sixty six-54max torque120-500NM,It can be linked(foot or flange)discretionary and use multi-mounting positions in accordance customers’ requirements1 Ground-hardened helical gears2. Modularity, can be merged in several forms3. Aluminum casing, mild weight4. Gears in carbonize tough,durable5. Common mounting6. Refined layout, RV050 .5HP 370W Worm Gearbox with Motor compact in composition and reduced sound

Organization details

Good quality handle

Packing&Shipping

Packing Particulars : Common carton/Pallet/Common picket scenarioShipping Details : fifteen-30 working times CZPT payment

Related Product

Main item listing: 16 series such as SLR/SLS/SLK/SLF sequence tough tooth flank equipment reducer , SLRC collection aluminium situation helical equipment reducers,SLHSLB series high electrical power pace reducer, SLP sequence planetary speed reducer, X/B series cycloidal reducer, SLXG sequence shaft-mounted equipment box, SLSWL series worm screw jack, SLT collection helical cone gear box, entirely a lot more than 10,000 ratios, numerous specification make us at the head of domestic transmission sector, widely provide the mechanical transmission subject of gentle & hefty market these kinds of as: beer & beverage, mining device, foods packing, textile printing, rubber & plastic substance, KSOP5-sixteen low sound screw oil free of charge piston air compressor for 5L oxygen concentrator petrochemical market, jack-up transportation, pharmacy & procedure hides, environmental safety products.

Precision Planetary gearbox

| Precision Planetary gearbox | Robotic RV gearbox velocity reducer |

| Custom made made Non-normal Gearbox | UDL Sequence Variator |

| PYZ Collection Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Series Planetary Reducer | SLH/SLB Collection High Power Reducer |

| NMRV Collection Worm Reducer | BKM Series Helical-hypoid Reducer |

| SLRC Series Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Series Shaft Mounted Reducer | X/B Series Cycloidal Reducer |

| SLR/SLF/SLK/SLS Collection Helical Reducer | AC/DC Motor |

FAQone.Payment Time period: TT, L/C

2.Delivery time: about thirty days from get payment.

three.We accept personalized merchandise as per your special requirement.

four.Xihu (West Lake) Dis.strains for the Variety:Typically we can choose 1 device which is suitable for you with some informations from you,this kind of as ratio/motor speed/mounting dimension/ out torque and many others.

five.If the minimum order amount is in extra of $ten thousand, there are preferential.

Q1: What data ought to I notify you to confirm the merchandise?

A:Product/Dimension, Transmission Ratio, Shaft instructions & Order quantity.

Q2: What can i do if I will not know which 1 I need to have?

A:Dont fear, Send out as much information as you can, our crew will assist you uncover the right 1 you are hunting for.

Q3: What is your solution warranty time period?

A:We offer 1 yr guarantee since the vessel departure day remaining China.

Q4: Are you buying and selling business or producer ?

A: We are manufacturing facility.

Q5: How prolonged is your delivery time?

A: Normally it is 5-10 days if the goods are in inventory. or it is fifteen-20 days if the products are not in stock, it is in accordance to quantity.

Q6: Do you provide samples ? is it free of charge or further ?

A: Yes, we could provide the sample for free demand but do not pay out the cost of freight.

Q7: What is your conditions of payment ?

A: Payment=1000USD, 30% T/T in advance , CZPT New Configuration air-compressors 185 CFM a hundred forty five CZPT 8bar 48kw 65HP portable screw air compressor diesel 190cfm HG190-8C stability ahead of shippment.

If you have any other questions, make sure you really feel free to make contact with us as demonstrated under, you can click on on the graphic under to get in touch with me directly.

Get in touch with us

How to Identify a Faulty Drive Shaft

The most common problems associated with automotive driveshafts include clicking and rubbing noises. While driving, the noise from the driver’s seat is often noticeable. An experienced auto mechanic can easily identify whether the sound is coming from both sides or from one side. If you notice any of these signs, it’s time to send your car in for a proper diagnosis. Here’s a guide to determining if your car’s driveshaft is faulty:

Symptoms of Driveshaft Failure

If you’re having trouble turning your car, it’s time to check your vehicle’s driveshaft. A bad driveshaft can limit the overall control of your car, and you should fix it as soon as possible to avoid further problems. Other symptoms of a propshaft failure include strange noises from under the vehicle and difficulty shifting gears. Squeaking from under the vehicle is another sign of a faulty driveshaft.

If your driveshaft fails, your car will stop. Although the engine will still run, the wheels will not turn. You may hear strange noises from under the vehicle, but this is a rare symptom of a propshaft failure. However, you will have plenty of time to fix the problem. If you don’t hear any noise, the problem is not affecting your vehicle’s ability to move.

The most obvious signs of a driveshaft failure are dull sounds, squeaks or vibrations. If the drive shaft is unbalanced, it is likely to damage the transmission. It will require a trailer to remove it from your vehicle. Apart from that, it can also affect your car’s performance and require repairs. So if you hear these signs in your car, be sure to have it checked by a mechanic right away.

Drive shaft assembly

When designing a propshaft, the design should be based on the torque required to drive the vehicle. When this torque is too high, it can cause irreversible failure of the drive shaft. Therefore, a good drive shaft design should have a long service life. Here are some tips to help you design a good driveshaft. Some of the main components of the driveshaft are listed below.

Snap Ring: The snap ring is a removable part that secures the bearing cup assembly in the yoke cross hole. It also has a groove for locating the snap ring. Spline: A spline is a patented tubular machined element with a series of ridges that fit into the grooves of the mating piece. The bearing cup assembly consists of a shaft and end fittings.

U-joint: U-joint is required due to the angular displacement between the T-shaped housing and the pinion. This angle is especially large in raised 4x4s. The design of the U-joint must guarantee a constant rotational speed. Proper driveshaft design must account for the difference in angular velocity between the shafts. The T-bracket and output shaft are attached to the bearing caps at both ends.

U-joint

Your vehicle has a set of U-joints on the driveshaft. If your vehicle needs to be replaced, you can do it yourself. You will need a hammer, ratchet and socket. In order to remove the U-joint, you must first remove the bearing cup. In some cases you will need to use a hammer to remove the bearing cup, you should be careful as you don’t want to damage the drive shaft. If you cannot remove the bearing cup, you can also use a vise to press it out.

There are two types of U-joints. One is held by a yoke and the other is held by a c-clamp. A full ring is safer and ideal for vehicles that are often used off-road. In some cases, a full circle can be used to repair a c-clamp u-joint.

In addition to excessive torque, extreme loads and improper lubrication are common causes of U-joint failure. The U-joint on the driveshaft can also be damaged if the engine is modified. If you are driving a vehicle with a heavily modified engine, it is not enough to replace the OE U-joint. In this case, it is important to take the time to properly lubricate these components as needed to keep them functional.

tube yoke

QU40866 Tube Yoke is a common replacement for damaged or damaged driveshaft tubes. They are desirably made of a metallic material, such as an aluminum alloy, and include a hollow portion with a lug structure at one end. Tube yokes can be manufactured using a variety of methods, including casting and forging. A common method involves drawing solid elements and machining them into the final shape. The resulting components are less expensive to produce, especially when compared to other forms.

The tube fork has a connection point to the driveshaft tube. The lug structure provides attachment points for the gimbal. Typically, the driveshaft tube is 5 inches in diameter and the lug structure is 4 inches in diameter. The lug structure also serves as a mounting point for the drive shaft. Once installed, Tube Yoke is easy to maintain. There are two types of lug structures: one is forged tube yoke and the other is welded.

Heavy-duty series drive shafts use bearing plates to secure the yoke to the U-joint. All other dimensions are secured with external snap rings. Yokes are usually machined to accept U-bolts. For some applications, grease fittings are used. This attachment is more suitable for off-road vehicles and performance vehicles.

end yoke

The end yoke of the drive shaft is an integral part of the drive train. Choosing a high-quality end yoke will help ensure long-term operation and prevent premature failure. Pat’s Driveline offers a complete line of automotive end yokes for power take-offs, differentials and auxiliary equipment. They can also measure your existing parts and provide you with high quality replacements.

A U-bolt is an industrial fastener with threaded legs. When used on a driveshaft, it provides greater stability in unstable terrain. You can purchase a U-bolt kit to secure the pinion carrier to the drive shaft. U-bolts also come with lock washers and nuts. Performance cars and off-road vehicles often use this type of attachment. But before you install it, you have to make sure the yoke is machined to accept it.

End yokes can be made of aluminum or steel and are designed to provide strength. It also offers special bolt styles for various applications. CZPT’s drivetrain is also stocked with a full line of automotive flange yokes. The company also produces custom flanged yokes for many popular brands. Since the company has a comprehensive line of replacement flange yokes, it can help you transform your drivetrain from non-serviceable to serviceable.

bushing

The first step in repairing or replacing an automotive driveshaft is to replace worn or damaged bushings. These bushings are located inside the drive shaft to provide a smooth, safe ride. The shaft rotates in a rubber sleeve. If a bushing needs to be replaced, you should first check the manual for recommendations. Some of these components may also need to be replaced, such as the clutch or swingarm.

editor by czh 2023-03-02

in Mexico City Mexico sales price shop near me near me shop factory supplier Helical Spur Gear Cylindrical Transmission Parts Shaft DC Motor Pin Bore Tooth Miniature Manufacturer Good Price Best Quality for Gearbox Auto Helical Spur Gear manufacturer best Cost Custom Cheap wholesaler

With a lot of years’ encounter in this line, we will be dependable by our positive aspects in aggressive value, a single-time shipping, prompt response, on-hand engineering assistance and very good soon after-income companies.Additionally, all our manufacturing methods are in compliance with ISO9001 expectations. We are aiming to meet the needs of the consumers close to the entire world.. Our specialists and engineers have 23 several years of Encounter in the Bearing Sector.

EPTcal Spur EPT Cylindrical EPTT Components Shaft DC EPT Pin Bore Tooth Miniature EPT Great Price tag EPTT EPTT for EPTT Auto EPTcal Spur EPT

Spur EPTs are a variety of cylindrical EPT, with shafts that are pXiHu (West EPT) Dis.Hu (West EPT) Dis.lel and coplanar, and teeth that are straigEPTT and oriEPTTd pXiHu (West EPT) Dis.Hu (West EPT) Dis.lel to the shafts. They’re arguably the most straightforward and most frequent type of EPT – effortless to manufacture and appropriate for an array of programs.

one.EPT: Alloy Metal, EPTT Metal, Stainless Steel, Harden amp Tempered Metal, Solid Iron, EPTT, Copper, Brass EPT and so on.

2. Heat Treatment: Hardening and Tempering, EPT Frequency Quenching, Carburizing Quenching and so on.

3. Pilot bore, completed bore, EPTTr bore and EPTT bore.

four. BrigEPTT floor and substantial precision

5. Advanced warmth therapy and floor treatment craft

6. EPTer high quality and aggressive price.

seven. Hassle-free to transport and handle

eight. EPT strength

nine. Corrosion resistance

10. EPT to install

11. EPTT life span

twelve. OEM/ODM welcome

There are two primary kinds of spur EPTs: exterior and internal. Exterior EPTs have the tooth that are lower externally area location of the cylinder. Two external EPTs mesh with each other and rotate in opposite instructions. Inner EPTs, in contrast, have tooth that are lower on the inside area of the cylinder. An exterior EPT sits within the inside EPT, and the EPTs rotate in the identical direction. Since the shafts are positioned nearer collectively, interior EPT assemblies are far more compact than external EPT assemblies. Inner EPTs are primarily used for planetary EPT EPTs.

Best China manufacturer & factory Hot sale Coaxial TRC helical gear box with high torque speed reducer gearbox transmission With high quality best price

With many years’ experience in these lines, we have been distinguished from other suppliers in China by our advantages in competitive pricing, on-time delivery, prompt responses, on-hand engineering support and good after-sales services.

Overview

Quick Details

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining, Construction works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

3.5~500N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

3.77~50.4

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

C&U,LYC, HRB,ZWZ,NSK

- Warranty:

-

1 Year

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

Hot sale Coaxial TRC helical gear box with high torque speed reducer gearbox transmission

Product Description

RC series small speed transmission reducer gearbox

The highly modular is a design featuEPG Drive is a world leader in double enveloping worm gear technology, which delivers drive solutions with the highest torque and shock load capacity in the smallest amount of space. EPG Drive is capable of designing and manufacturing precision gearing solutions for many applications. EPG Drive serves an entire spectrum of mechanical drive applications from packaging, material handling, mining and metals to automotive, aerospace and medical equipment.res of SRC helical gearboxes range. It can be connected respectively with motors such as normal motor,brake motor,explosion-proof motor,frequency conversion motor,servThe star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.o motor,IEC motor and so on. This kind of product is widely used in drive fields such as textile,foodstuff,ceramics packing,logistics,plastics and so on. It is possible to set up the version required using flanges or feet.

Product features:

SLRC series helical gear units has more than 4 types,power 0.12kw-4kw,ratio3.66-54;max torque120-500NM,It can be connected(foot or flange)discretionary and use multi-mounting positions according customers’ requirements

1 Ground-hardened helical gears

2. Modularity, can be combined in many forms

3. Aluminum casing, light weight

4. Gears in carbonize hard,durable

5. Universal mounting

6. Refined design, compact in structure and low noise

| Certification | ISO9001-2008 |

| Bearing | C&U |

| Color | Blue/black |

| Ratio | 3.77~50.4 |

| Mount Position | Foot Mounted |

| Bearing | LYC, HRB,ZWZ,SKF,NSK |

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us

Best China manufacturer & factory china supplier H B Bevel helical reduction gearbox 50:1 for bucket elevators With high quality best price

Due to our wide product range and rich experiences in this industry, we are confident to provide our customers flexible and diversified services.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

single stage two stage three stage four stage

- Ratio:

-

1.25-90

- Housing Material:

-

Cast Iron

- Material:

-

20CrMnTi

- Working temperature:

-

-40~45℃

- Type:

-

H B Bevel helical reduction gearbox 50:1 for bucket elevators

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Year H B Bevel helical reduction gearbox 50:1 for bucket elevators

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for H B Bevel helical reduction gearbox 50:1 for bucket elevators

- Port

- Qingdao

-

Lead Time

: -

Quantity(Bags) 1 – 20 How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

>20 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

H B Series Industrial GearBox

Ever-Power Machinery —— Tianqi Brand industrial gearbox manufacturers

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Specification

HB Industrial Gearbox:

| Type | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

Type | n r/min |

Transmission Ratio (i) |

| H1SH | 750 | 1.25-2 | H2 B2 | 750 | 5-9 | H3 B3 | 750 | 12.5-112 | H4 B4 | 750 | 80-450 |

| 2.24-5.6 | 10-28 | 1000 | 12.5-112 | 1000 | 80-450 | ||||||

| 1000 | 1.25-2 | 1000 | 5-9 | 1500 | 12.5-31.5 | 1500 | 80-112 | ||||

| 2.24-5.6 | 10-28 | 35.5-56 | 125-450 | ||||||||

| 1500 | 1.25-2 | 1500 | 5-6.3 | 63-112 | |||||||

| 4-5.6 | 7-9 | ||||||||||

| 10-16 | |||||||||||

| 18-28 | |||||||||||

Mounting Diamension:

(please contact us for more types & model)

Feature:

-

Realized parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes. Using less component parts.

-

Applying advanced grinding process which improved the stability and the efficiency of transmit power with lower noise.H B Bevel helical reduction gearbox 50:1 for bucket elevators.

-

Input mode: motor connected flange, shaft input.

-

Output mode:solid shaft with flat key,hollow shaft with flat key,hollow shaft with shrink disk,hollow shaft with spline connection, solid shaft with spline connection, solid shaft with flange.

-

Mounting mode:vertical, horizontal, swing base-mounted, torque-arm-mounted.

-

Ratio range:1.23~450. It can be higher when combining with K&R series reducer.

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.Industrial Gearbox Manufacturers H B Series High rpm Gearbox Reduction with 6: 1 ratio.H B Bevel helical reduction gearbox 50:1 for bucket elevators.

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The c EPG is specialized in design, manufacturer and sales of agricultural machinery and farm implements, which has an independent import and export rights. ompany has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

Technology

Chinese Gear Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of RedIndustry Knowledge Having worked closely with our customers, EPG ’s staff have amassed a wealth of knowledge of industry specific applications and requirements, ensuring the right product for the process.ucer products.Industrial Gearbox Manufacturers H B Series High rpm Gearbox Reduction with 6: 1 ratio.H B Bevel helical reduction gearbox 50:1 for bucket elevators.1:40 ratio.3: 1 ratio gearbox.1:30 ratio gearbox.

Packaging & Shipping

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

China best quality low sales price for china manufacturer factory of R series helical gearbox Factory Manufacturer and Supplier -from Pto-shaft.com

Our business is situated in XiHu HangZhou Zhejiang Province. T

Overview

Swift Information

- Applicable Industries:

-

EPT Plant

- Coloration:

-

Blue

- Application:

-

Equipment Device

- Ratio:

-

21342~seven.25

- Solution Keywords and phrases:

-

reductor

- Material:

-

20CrMnTi

- Packing:

-

Wooden Box

- Sort:

-

Transmission Gear

- Fat:

-

20kg—2000kg

- Bearing:

-

N EPT Bearing

- Keyword:

-

S collection

Packaging & Shipping and delivery

-

Lead Time

: -

Quantity(Baggage) one – 5 six – twenty >20 Est. Time(times) 7 20 To be negotiated

On the internet Customization

Solution Description

Our Factory

Pac ept & Supply

Software area

FAQ

Q1: Are you ept organization or manufacturer ?

A: We are a company in ZJ China.welcome to our manufacturing unit to have a pay a visit to.

Q2: How we choose method EPT and requirements?

A:You can electronic mail us the collection identify & code (for example: WJ series worm gearbox) as nicely as prerequisite specifics. this sort of as motor electricity. output pace or ratio. support factor or your software…as significantly information as feasible. If you can offer some images or drawings. it is far better.

Q3: How is your value? Can you offer you any price reduction?

A: We will give the be EPT price tag we can base on your requirements and the quantities.

This fall: How long should I wait for the suggestions right after I deliver the enquiry?

A: In twelve hours.

EPG – As one of the greatest machinery transmission and agricultural part and tools manufacturing unit in China, we will supply your large high quality items with least expensive price. We update new items month-to-month from pto-shaft.com

R Chinese Factory Wholesaler & Exporter series type bevel helical transmission gearbox speed reducer gear motor box for conveyor reverse gearbox for buggy

The team is centered on producing all selection of standard roller chains and sprockets, gears & gearboxes, this kind of as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just sold its goods all over china, but also marketed a lot more than 65% items to oversees, including Europe, America, South-east Asia, and it also has set up storage logistics in locations like Europe.

Overview

Swift Details

- Applicable Industries:

-

Hotels, Garment Stores, Creating Materials Outlets, Manufacturing Plant, Machinery Restore Shops, Farms, Strength & Mining, Building functions

- Area of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Speed:

-

1400rpm

- Output Pace:

-

14-280rpm

- Ratio:

-

seven.five~one hundred

- Certification:

-

ISO9001-2008

- Mount Situation:

-

Foot Mounted

- Bearing:

-

LYC,

Supply Capacity

- Source Capacity:

- 500 Device/Models for every Month

Packaging & Delivery

- Packaging Details

- Wood bins , Cantons packed in one pallet

- Port

- Ningbo Port, Shanghai Port

On the internet Customization

R collection type bevel helical transmission gearbox pace reducer gear motor box for conveyor reverse gearbox for buggy

Product Description

SLR helical reducer has the attributes of large versatility,good combination and heavy loading ability, together with other deserves these kinds of as effortless to attain a variety of transmission ratios, high effectiveness, lower vibrationand high permissible axis radial load. This series can not only be blended with a variety of kinds of reducers and variators and satisfy the demands, but also beadvantage of localization of associated transmission gear.

Specifications:

1) Output speed: .6~one,028r/min

two) Output torque: up to eighteen,000N.m

3) Motor electricity: .eighteen~160kW

four) Mounted type: foot-mounted and flange-mounted mounting

|

Merchandise Name |

SLR Sequence Rigid Tooth helical reducer |

|

Gear Content |

20CrMnTi |

|

Situation Material |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding complete by HOFLER Grinding Machines |

|

Color |

Personalized |

|

Sound Check |

Bellow 65dB |

Organization Info

Certifications

Packaging & Shipping and delivery

Relevant Goods

Our Solutions

FAQ

: Are you investing company or company ?

A: We are manufacturing facility.

Q: How prolonged is your delivery time?

A: Normally it is 5-10 times if the goods are in inventory. or it is 15-20 times if the items are not in inventory, it is according to quantity.

Q: Do you provide samples ? is it free of charge or extra ?

A: Of course, we could provide the sample for totally free demand but do not pay the cost of freight.

Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in advance ,balance ahead of shippment.

If you have yet another question, pls come to feel cost-free to contact us as underneath:

Speak to us