Product Description

| SHIPPING(Normally arrive port time in working days) | ||||

| Destination | Express/Courier | Ship by sea | Ship by air | Ship by EMS |

| DHL/FedEx/UPS/SF | ||||

| North America | 3-7 days | 15-24 days | 5-7 days | 10-12 days |

| South America | 3-7 days | 15-25 days | 5-7 days | 10-12 days |

| European Countries | 3-7 days | 20-30 days | 5-7 days | 10-12 days |

| Africa Countries | 3-7 days | 40-50 days | 5-7 days | 10-12 days |

| The Middle East | 3-7 days | 15-25 days | 5-7 days | 10-12 days |

| Australia | 3-7 days | 10-15 days | 5-7 days | 10-12 days |

Company Profile

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in our W brand box ..

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, most of items we keep stock for all season . it will take 7to 10 days after receiving your advance payment. .if we didn’t have stock ,The delivery time depends on the items and the quantity of your order. Normaly 30 to 60days .

Q5. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you inspect all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7. How do you make our business long-term and good relationship?

1.Meet small quantity orders and seasonal orders by our sufficient safety stock;

2.Assure best quality with our complete inspection system before shipment

3.Ensure timely delivery to customer’s designated site by our professional management of warehouse and van fleet;

4.Provide in time Feedback tracking and after-sales services to maximize the customer’s satisfactory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

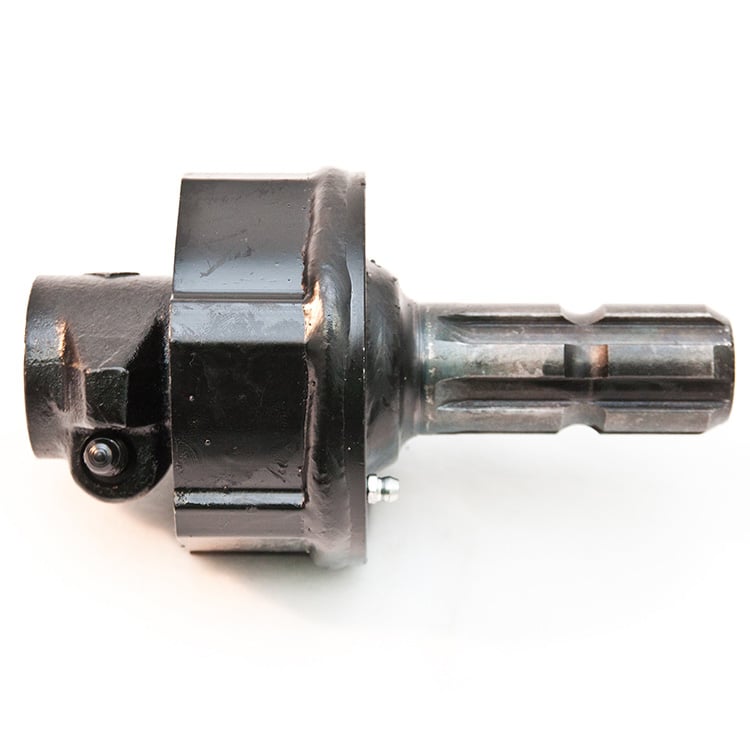

| Type: | Shaft |

|---|---|

| Usage: | Tractor |

| Material: | Iron |

| Power Source: | – |

| Weight: | – |

| After-sales Service: | Optional |

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

Can drive shafts be customized for specific vehicle or equipment requirements?

Yes, drive shafts can be customized to meet specific vehicle or equipment requirements. Customization allows manufacturers to tailor the design, dimensions, materials, and other parameters of the drive shaft to ensure compatibility and optimal performance within a particular vehicle or equipment. Here’s a detailed explanation of how drive shafts can be customized:

1. Dimensional Customization:

Drive shafts can be customized to match the dimensional requirements of the vehicle or equipment. This includes adjusting the overall length, diameter, and spline configuration to ensure proper fitment and clearances within the specific application. By customizing the dimensions, the drive shaft can be seamlessly integrated into the driveline system without any interference or limitations.

2. Material Selection:

The choice of materials for drive shafts can be customized based on the specific requirements of the vehicle or equipment. Different materials, such as steel alloys, aluminum alloys, or specialized composites, can be selected to optimize strength, weight, and durability. The material selection can be tailored to meet the torque, speed, and operating conditions of the application, ensuring the drive shaft’s reliability and longevity.

3. Joint Configuration:

Drive shafts can be customized with different joint configurations to accommodate specific vehicle or equipment requirements. For example, universal joints (U-joints) may be suitable for applications with lower operating angles and moderate torque demands, while constant velocity (CV) joints are often used in applications requiring higher operating angles and smoother power transmission. The choice of joint configuration depends on factors such as operating angle, torque capacity, and desired performance characteristics.

4. Torque and Power Capacity:

Customization allows drive shafts to be designed with the appropriate torque and power capacity for the specific vehicle or equipment. Manufacturers can analyze the torque requirements, operating conditions, and safety margins of the application to determine the optimal torque rating and power capacity of the drive shaft. This ensures that the drive shaft can handle the required loads without experiencing premature failure or performance issues.

5. Balancing and Vibration Control:

Drive shafts can be customized with precision balancing and vibration control measures. Imbalances in the drive shaft can lead to vibrations, increased wear, and potential driveline issues. By employing dynamic balancing techniques during the manufacturing process, manufacturers can minimize vibrations and ensure smooth operation. Additionally, vibration dampers or isolation systems can be integrated into the drive shaft design to further mitigate vibrations and enhance overall system performance.

6. Integration and Mounting Considerations:

Customization of drive shafts takes into account the integration and mounting requirements of the specific vehicle or equipment. Manufacturers work closely with the vehicle or equipment designers to ensure that the drive shaft fits seamlessly into the driveline system. This includes adapting the mounting points, interfaces, and clearances to ensure proper alignment and installation of the drive shaft within the vehicle or equipment.

7. Collaboration and Feedback:

Manufacturers often collaborate with vehicle manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft customization process. By actively seeking input and feedback, manufacturers can address specific needs, optimize performance, and ensure compatibility with the vehicle or equipment. This collaborative approach enhances the customization process and results in drive shafts that meet the exact requirements of the application.

8. Compliance with Standards:

Customized drive shafts can be designed to comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, ensures that the customized drive shafts meet quality, safety, and performance requirements. Adhering to these standards provides assurance that the drive shafts are compatible and can be seamlessly integrated into the specific vehicle or equipment.

In summary, drive shafts can be customized to meet specific vehicle or equipment requirements through dimensional customization, material selection, joint configuration, torque and power capacity optimization, balancing and vibration control, integration and mounting considerations, collaboration with stakeholders, and compliance with industry standards. Customization allows drive shafts to be precisely tailored to the needs of the application, ensuring compatibility, reliability, and optimal performance.

What is a drive shaft and how does it function in vehicles and machinery?

A drive shaft, also known as a propeller shaft or prop shaft, is a mechanical component that plays a critical role in transmitting rotational power from the engine to the wheels or other driven components in vehicles and machinery. It is commonly used in various types of vehicles, including cars, trucks, motorcycles, and agricultural or industrial machinery. Here’s a detailed explanation of what a drive shaft is and how it functions:

1. Definition and Construction: A drive shaft is a cylindrical metal tube that connects the engine or power source to the wheels or driven components. It is typically made of steel or aluminum and consists of one or more tubular sections with universal joints (U-joints) at each end. These U-joints allow for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components.

2. Power Transmission: The primary function of a drive shaft is to transmit rotational power from the engine or power source to the wheels or driven components. In vehicles, the drive shaft connects the transmission or gearbox output shaft to the differential, which then transfers power to the wheels. In machinery, the drive shaft transfers power from the engine or motor to various driven components such as pumps, generators, or other mechanical systems.

3. Torque and Speed: The drive shaft is responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). The drive shaft must be capable of transmitting the required torque without excessive twisting or bending and maintaining the desired rotational speed for efficient operation of the driven components.

4. Flexible Coupling: The U-joints on the drive shaft provide a flexible coupling that allows for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components. As the suspension system of a vehicle moves or the machinery operates on uneven terrain, the drive shaft can adjust its length and angle to accommodate these movements, ensuring smooth power transmission and preventing damage to the drivetrain components.

5. Length and Balance: The length of the drive shaft is determined by the distance between the engine or power source and the driven wheels or components. It should be appropriately sized to ensure proper power transmission and avoid excessive vibrations or bending. Additionally, the drive shaft is carefully balanced to minimize vibrations and rotational imbalances, which can cause discomfort, reduce efficiency, and lead to premature wear of drivetrain components.

6. Safety Considerations: Drive shafts in vehicles and machinery require proper safety measures. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts and reduce the risk of injury in the event of a malfunction or failure. Additionally, safety shields or guards are commonly installed around exposed drive shafts in machinery to protect operators from potential hazards associated with rotating components.

7. Maintenance and Inspection: Regular maintenance and inspection of drive shafts are essential to ensure their proper functioning and longevity. This includes checking for signs of wear, damage, or excessive play in the U-joints, inspecting the drive shaft for any cracks or deformations, and lubricating the U-joints as recommended by the manufacturer. Proper maintenance helps prevent failures, ensures optimal performance, and prolongs the service life of the drive shaft.

In summary, a drive shaft is a mechanical component that transmits rotational power from the engine or power source to the wheels or driven components in vehicles and machinery. It functions by providing a rigid connection between the engine/transmission and the driven wheels or components, while also allowing for angular movement and compensation of misalignment through the use of U-joints. The drive shaft plays a crucial role in power transmission, torque and speed delivery, flexible coupling, length and balance considerations, safety, and maintenance requirements. Its proper functioning is essential for the smooth and efficient operation of vehicles and machinery.

editor by CX 2024-04-25

China manufacturer & factory supplier for Best in San Jose del Monte Philippines quality farm parts k700 tractor gearbox 700A.17.17.000 With high quality best price & service

We seem ahead to the possibility to provide you and hope to incorporate you to our expanding family of happy consumers.Our items are manufactured by contemporary computerized machinery and equipment.a specialised provider of a full variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Specifics

- Applicable Industries:

-

Production Plant

- Product Identify:

-

farm components k700 tractor gearbox 700A.17.17.000

- Application:

-

Tactors

- Material:

-

Casting

- Certificate:

-

ISO9001:2008

- Dimension:

-

64*eighteen*32CM

- Excess weight:

-

12kg

- Tractor Model Compatability:

-

K700

- High quality:

-

one hundred%tested

- OEM:

-

Accpet

- Brand name:

-

EP

Offer Ability

- Provide Potential:

- 5000 Established/Sets per Day

Packaging & Shipping and delivery

- Packaging Information

- Packaging Details

- Port

- Tianjin xingang port, Lianyungang port. Yiwu port, Shanghai

-

Lead Time

: -

Quantity(Luggage) –Driven (outer) yoke very same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their styles. Domestic are generally a single of 4 styles: round, square, rectangle or splined. Metric are: bell, star or football formed. In both case the main (front) shaft is the very same form as the secondary shaft, only greater so that the secondary shaft suits within. This makes it possible for a telescoping influence to take location when the apply is lifted on the 3 pt. or throughout a turning movement these kinds of as a bailer. All shafts have to be sized prior to use. Connect the apply to the 3 pt. and increase and assist it. Connect the correct stop to the tractor and endeavor to attach the other to the apply. If the shaft is as well long trim one particular of the shafts with a hack saw and try out it again until it fits. This allows for the implement to be raised without having binding. The shafts must overlap as much as allowed.

1 – one thousand >1000 Est. Time(days) five To be negotiated

On-line Customization

| Applicable Industries | Equipment Repair Shops,Farms |

| Type | equipment boxes k700 |

| Use | Tractors |

| Location of Origin | China |

| Brand Identify | PARUC |

| Product Title | farm parts k700 tractor gearbox 700A.seventeen.seventeen.000 |

| Software | Tactors |

| Material | Casting |

| Certification | ISO9001:2008 |

| Size | sixty four*eighteen*32CM |

| Bodyweight | 12kg |

| Tractor Product Compatability | K700 |

| Good quality | 100%tested |

| OEM | Accpet |

| Brand name | EP |

If you want any favorable or quick transport welcome to speak to us

Q1:How your business usually transports merchandise to your countriEPG Drive is a world leader in double enveloping worm equipment technology, which delivers generate answers with the maximum torque and shock load potential in the smallest quantity of room. EPG Generate is capable of designing and production precision gearing solutions for numerous programs. EPG Push serves an entire spectrum of mechanical drive applications from packaging, substance handling, mining and metals to automotive, aerospace and medical products.es?

This issue is mostly established by the quantity of the goods. If the number of orders is sufficient for a container, it is advised that containers be shipped by sea or rail if the amount of orders is small, they can be delivered by the shipping and delivery business.

Q2:Is your company’s items retailable?

Sorry, we do not settle for retail orders. Our order quantity is established in accordance to the packaging of the goods. For instance, if there are thirty circumstances in a single box, then 30 are the least expensive buy amount.

Q3:What is the payment technique?

If it is a location, we need to acquire the complete payment just before they can be transported if it is an order, then in accordance to the pay as you go thirty%, the remaining 70% of the payment ahead of the deal to indicator the contract.

EPG is specialized in style, producer and product sales of agricultural equipment and farm implements, which has an unbiased import and export legal rights.

Made sales made in China – replacement parts – pto shaft pin stuck in China High Quality, Good Performance Tractor with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing unit in China with 5 different branches. For much more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

2009 ford f150 push shaft The 540 pto shaft with slip clutch organization rc boat propeller shaft masking tractor pto shaft canada 88,000 pto shaft 4 sale sq. weasler pto shaft meters, sprinter propshaft has pto pump shaft advanced pto shaft ontario gear freelander driveshaft and strong technical power, these kinds of as the numerical control equipment resources and machining centers, CAD/CAM method, industrial robotic and so on. “EPG” manufacturer rotocultivator ploughshares in T.S. whole lines developed in our manufacturing facility have been examined and appraised by the Ministry of Agriculture and have attained the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic of China.

Tough Substantial Good quality Higher Horse-Power Tractor

Qualities:

Affordable and productive

Outfitted popular manufacturer engine. Torque reserve is big. The power is a lot more more powerful, gas use is much more reduced.

18F+6R change with resonable distributing, can adapt to various functions with far more successful doing work and much better gas economy.

Undertake 17-inch strengthened imported diaphragm solitary-acting clutch a lot more flexible running and larger trustworthiness

Italy CARRARO entrance travel axle has a higher dependability

Adopt American Peel bearing. It has much better anti-tiredness and much better high quality stability.

Optional Trelleborg radial tires, with choice of front and rear double whee EPT or one wheels, higher efficiency and reduced gasoline intake.

Risk-free and safe, reputable

The gearbox functions a reinforced housing, synchronizer, shuttle shift, and entire helical equipment push for much more flexible, lightweight and dependable procedure.

4-wheel generate, PTO, differential lock, and so forth. use damp clutch and electro-hydraulic manage, which is mild and straightforward to operate.

Hydraulic technique has impartial oil provide, clutch hydraulic aid, light and adaptable procedure, substantial dependability.

The electric handle hydraulic lifting system is convenient and quick to operated, and can comprehend capabilities these kinds of as lifting, plow top adjustment, working force adjustment, lifting pace adjustment, computerized looking through and make a decision lifting failure and transportation mode management

Strengthened drive transmission and towing, reliable functionality and higher reliability.

Comfy and secure, driving easier

Technological Parameters:

Electrical power: 100hp, New boost massive chassis

Drive kind: 4 wheel drive

Motor: 4 cylinder, in-line motor, water cooled, 4 stroke, EPT engine

Shifts: 16F+8R Transmission box

Clutch: Twin-phase Clutch

Overall dimension: 4350×2130×2840 mm

Tread: entrance 1625mm, rear 1608-1996 mm

Wheelbase: 2380 mm

Min.floor clearance: four hundred mm

Outer high pressure hydraulic system

Steering: Hydraulic steering

Seat: Luxury seat with shock absorption

attery: Upkeep-free battery

Rear-situation 3 position suspension

PTO shaft: Rear-mounted, Twin-velocity PTO (760/850r/min), 6-teeth spline

Tire: Entrance 11.2-24, Rear 16.9-34 Front

Physical appearance:

FAQ:

1.Are you a manufacture or investing organization?

We are a skilled company and we can give tractors from 25Hp-220Hp and implements. .

two.what is your MOQ?

one unit.

three.How about the spare elements?

We can supply free of charge toolbox and straightforward broken areas.

four.In which is the loading port?

HangZhou port, or to meet up with client’s requirement.

five.How prolonged is the guide time?

Generally 15-25 times. Depands on the quantity of your buy.

6.How long is the guarantee time?

18 months following the goods shipping to spot port.

7.what is actually your payment phrases?

Typically we use T/T We also settle for other payment terms, such as Western Union, PayPal and L/C.

eight.what is actually the tractor optional areas?

Can be equipped with ROPS, Cover, Enthusiast cabin, Heater cabin, AC cabin, Air Brakes, Hydraulic valve out, Paddy tire, Turf tire or as for each your specifications.

nine.Can we use our very own symbol or layout?

Indeed.OEM is welcome any time. We can also give entire tractor product layout.

ten. Can be utilized for which implements?

Loader, Backhoe, Harrow, Mower, Plough, Planter, Trailer, Slasher, Snow blower or as per your needs.

Shipping and delivery:

Pre-revenue service

one. 24 several hours on the internet. Everything will be rapidly replied.

2. Skillfully and humanization modern day layout.

three. Welcome to going to our manufacturing facility, merchandise and design and style centre.

Offering service

1.Take a look at and inspect each and every tractor carefully and seriously.

2. Deliver the tractor pictures of your order ahead of packing for your affirmation

three. After loaded we will deliver you the transport data and arrival time. Finally, deliver all unique documents to you by Categorical or Mobile: +86~13083988828ex launch.

Following-sales service

one. 24 hours on the internet to resolve any difficulty.

2. English guide, Spare areas catalogue and complex assist.

three. Free of charge training for how to install the equipment and upkeep.

Best China manufacturer & factory china in Berlin Germany forging pto shaft yoke quick release yoke of pto drive shafts for agricultural tractor With high quality best price

It has established stable cooperation with many well known universities and institutes in china such as, Zhejiang University, Jilin University, Technical committee of national chain drive standard, Institute of national chain drive, Zhejiang application engineering material institute, Huhan material protection institute; and it cooperated to found China First Car chain institute with National chain drive institute.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Structure:

-

W or S

- Tube:

-

Triangular, Lemon, Star tube

Advantages of Worm Gears

- Process:

-

Forged

- Design:

-

Customized

- EPG is willing to cooperate sincerely and develop commonly with friends! Certificate:

-

CE Certificate

- Package:

-

Iron pallet&wooden carton&standard export packaging

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- NINGBO OR SHANGHAI

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Structure | W or S |

| Tube | Triangular, Lemon, Star tube |

| Process | Forged |

| Design | Customized |

| Certificate | CE Certificate |

| Package | Iron pallet&wooden carton&standard export packaging |

Product Display

Product Display

PTO Drive Line Gen …

18″ Heavy Duty Ear …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

How Can You Be Safe When Using PTO Shafts? First, make sure the shaft is shielded. This includes the driveline shield that covers the implement driveline, and the master shield which covers the universal joint and PTO stub shaft on the tractor.Maintain the shield so it can work for you. PTO driveline shields are usually mounted on bearings, so they need to be maintained. always REPLACE the shield when it is damaged or missing.Next, keep a safe distance from it when in use. Keep others away, too. How far? A distance of twice your height is a good start.Allow only those who absolutely must be in the area to be there. Keep all children away!Always pay attention to what is happening. Most PTO victims were caught by surprise.If something goes wrong — stop the machinery; take the PTO out of gear, stop the engine and set the brake. Put the keys in your pocket before working on the machinery.When stopping the machinery for any reason — end of work, lunch, repairs, or communication — take the PTO out of gear, stop the engine and set the brake.Road planers, dredges, and other equipment require power from some sort of engine in order to perform their designed function. Without a power take off, it would be necessary to add a second engine to provide the power necessary to run hydraulic pumps and other driveline attached equipment.

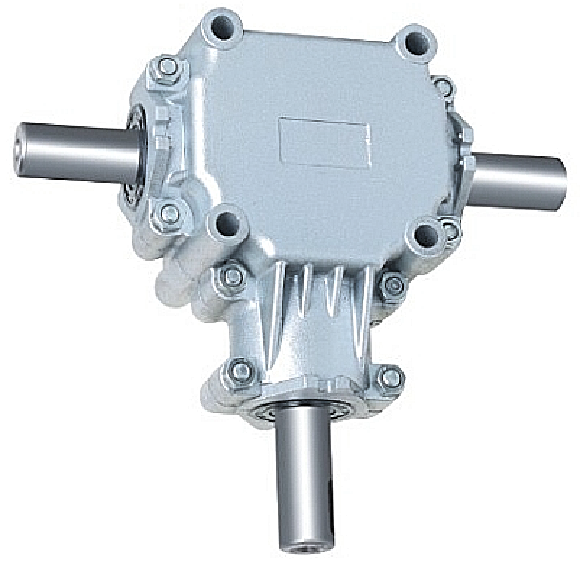

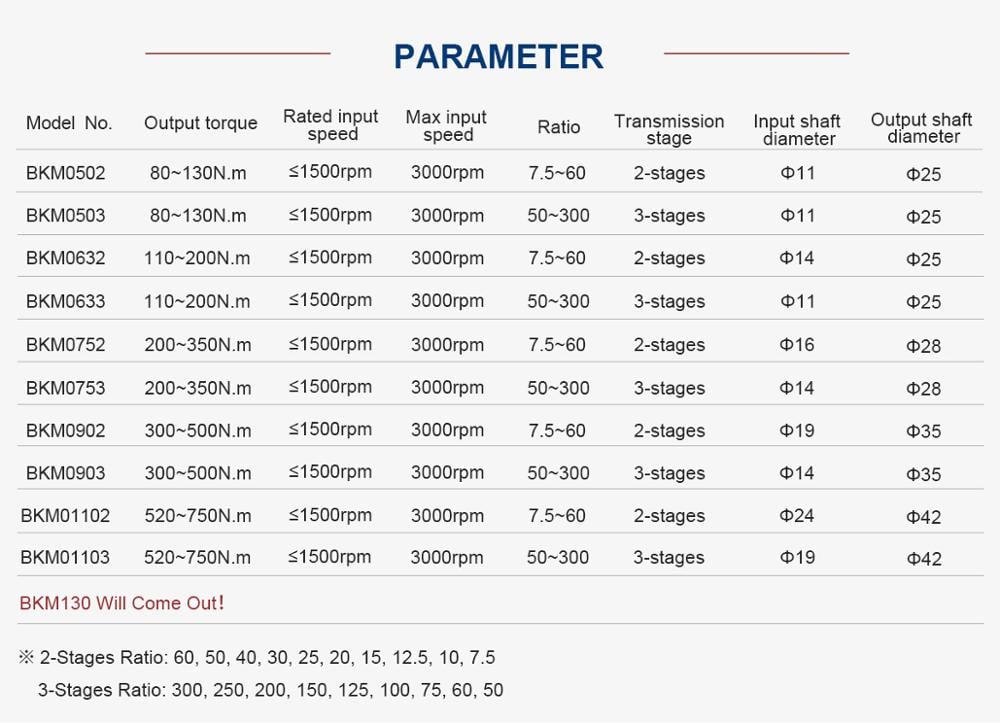

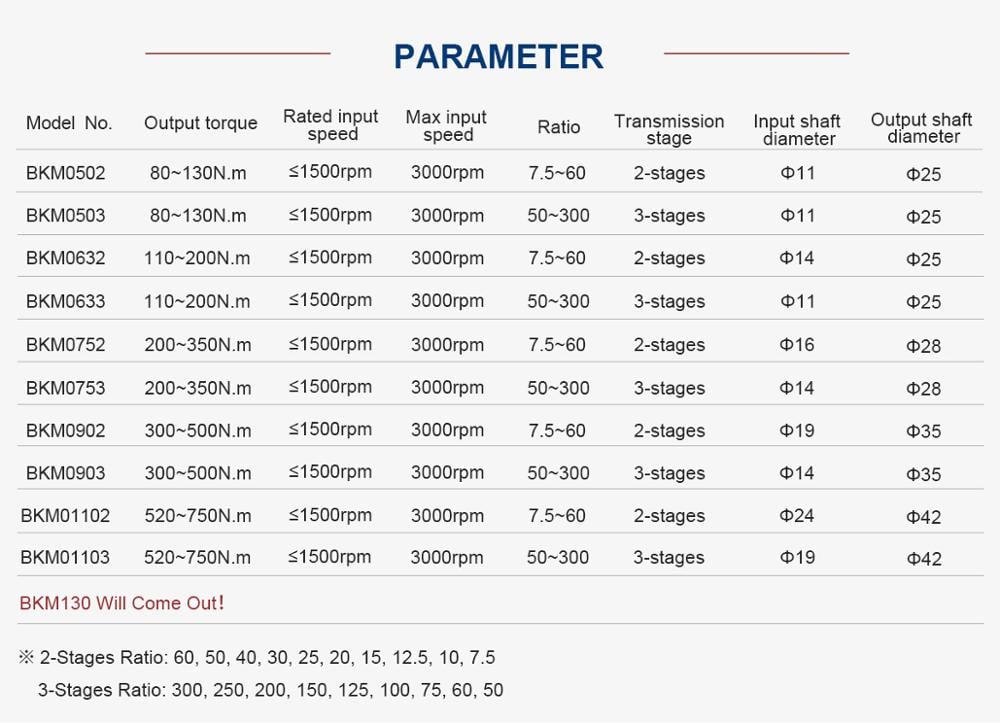

Best China manufacturer & factory china in Sharjah United Arab Emirates manufacturer BKM0633 industrial walking tractor bulldozer transmission gear box With high quality best price

specialize in power transmission products Chain,pto shaft, agricultural gearboxes , CATV products, mechanical seal, hydraulic and Pheumatic, and promotional products.

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country.

Overview

Quick Details

- Applicable Industries:

-

precision machinery

- Gearing Arrangement:

-

Hypoid

In our company we are aware of the importance of the users’ safety. That’s why our PTO’s are produced according to legal regulations and European directives and bear the CE sign. A key factor for safety assurance is the accession in the products’ development phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is vital. This means, that every users’ duty is to read and follow the safety instructions.

- Output Torque:

-

110~200 N.m

- Input Speed:

-

≤1500 rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

agricultural hypoid gearbox

- Ingress Protection:

-

IP65

- Ratio:

-

50~300

- Color:

-

gray /blue/black

- Heat treatment:

-

surface hardening

- Housing Material:

-

aluminum alloy

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

-

Lead Time

: -

Quantity(Sets) 1 – 1000 >1000 Est. Time(days) 30 To be negotiated

Online Customization

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced maWorm gears are typically manufactured by hobbing with a hob or cutting tool very similar to the worm that the gear mates with. The worm may be turned, hobbed, milled, or ground.nagement software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And – 100% inspect finished spare parts before put in storage. – 100% inspect before assembly. – 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

Best China manufacturer & factory Factory Directly Provide Good Quality Flexible Tractor Pto Shaft With high quality best price

With EPG brand registered in more than 70 countries like America , Europe , Japan and so on, it has partners among world top enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, etc.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

–Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.

- Certificate:

-

To address these sealing and efficiency issues, Emerson Power Transmission (EPT) developed several design and manufacturing recommendations. The resulting gearboxes tend to run cooler and leak free, compared with conventional worm gear units.

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- ningbo or shanghai

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

18″ Heavy Duty Ear …

Tie Rod Cylinder H …

12″ Diameter Compa …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usualOur products are selling well in Chinese markets and some products sold in international markets are well received by Chinese and foreign clients at home and abroad. ways we are using.

……

High China china pto shaft in Managua Nicaragua Quality Farm Machines Dq704G 70HP 4WD Agricultural Wheeled Farm Tractor with Ce Certificate with ce certificate top quality low price

We – EPG Team the most significant agricultural gearbox and pto factory in China with five distinct branches. For more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

Higher high quality farm machines DQ704G 70HP 4wd Agricultural wheeled Farm Tractor with CE certification

Tractor Principal Functions and Positive aspects:

one.Outfitted famous brand name engine displaying superior capacity,minimal gasoline consumption,substantial economic performance.

two. Streamlined look design, lovely and generous.

three.Transmission Case undertake meshed change and add the gearbox interlock system tends to make the operation much more efficiently,reputable and less difficult.

four. Double action clutch with disc spring, perform steadily and simple to run.

5. Totally hydraulic steering technique greatly lowered driver’s perform strength.

six. Soaked disc brake system, trustworthy brake efficiency.

seven. Separate injection of hydraulic oil, trustworthy to function.

eight. The lifter with force and position adjustment, with reliable carry.

9. Tractor PTO:

PTO in Double pace : 540/760 or a thousand r/min Optional, For high operating efficiency.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural equipment of all more than the world.

ten. Massive Chassis and Weighty-responsibility Rear axle for Sturdy Powerful equipment.

11. Complete series light-weight, ROPS,Sunshade/Canopy, Admirer/Heater/Air-conditioned cabin are all accessible, for a lot more comfy driving atmosphere.

Tractor Main specificaiton and Technological parameters:

DQ704G 70HP 4wd Tractor have diverse optional configurations for choose :

EPT Manufacutring Line:

Strictly Inspecting and Complete Tests for guaranteeing higher good quality solution:

Customlized Tractor Packing and Transporting support to meet different clients demand

You should Speak to us if you have any need for our Item

Very best value will be quoted for you as shortly as get your Necessity !